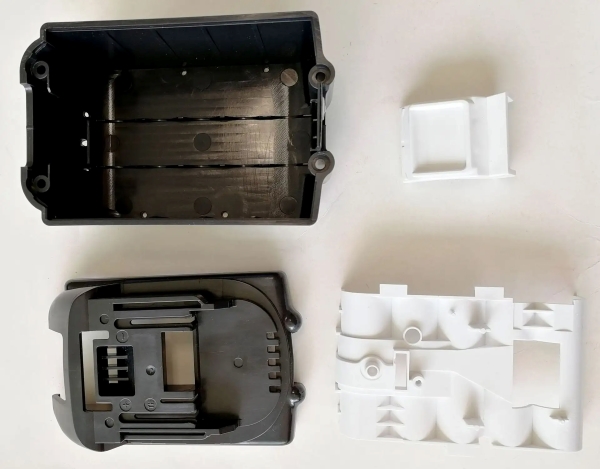

Due to the booming development of new energy vehicles, power lithium batteries as a powerful booster for the development of new energy vehicle technology, the application of new energy vehicles has great potential, therefore, the lithium battery production process is becoming increasingly mature, in different applications under different working conditions, the packaging requirements for lithium battery modules are not the same, such as the polymer shell packaging of lithium batteries and battery breathable waterproof device, metal and polymer plastic welding Currently, the main polymer materials used are PPA+GF30%, PA66+GF30%, PBT+GF30% and so on. This issue of Songsheng editorial briefly described laser plastic welding used in lithium battery plastic parts processing.

Laser plastic welding technology in lithium battery production applications

General lithium battery has a lot of electronic components inside, the conventional sealing has gluing or vibration welding, hot plate welding, and the use of vibration friction or ultrasonic welding, hot plate welding on the internal device has a direct or indirect impact or damage, and the use of gluing method, the current environmental protection than the high requirements, and the glue has an aging cycle, and in addition to consider from the cost point of view of the cost of gluing to be far higher than the cost of welding.

Due to the electronic components of the closure requirements are also relatively high, do not allow air leakage or leakage, the basic requirements for sealing requirements in the IP67 ~ IP69 level requirements, so the entire sealing requirements are still relatively high, from the welding product technology requirements to consider and welding quality, automation requirements, mass production point of view, the laser plastic welding is very ideal to meet the requirements of the process, the welding process can be realised! The welding process can achieve real-time closed-loop control to meet the requirements of automated production lines, in addition to real-time closed-loop control of the welding process, can be analysed according to the set technical parameters, to achieve automation of retrospective production.

Laser plastic welding utilises a high energy density laser beam as a heat source to heat the surface of the workpiece by laser radiation, which locally heats up and melts the material, thus joining the plastic materials. This technique is not only suitable for transparent and pure white thermoplastics, but can also handle all types of plastic materials.

Laser plastic welding system selection

1. According to the laser wavelength can be divided into: 976nm and 2um welding system.

2. 976nm laser welding system is widely used at present, 976nm laser welding principle adopts the principle of upper transmission + lower absorption to connect.

3.2um laser welding system, is the upper and lower parts at the same time heating, in the combination of the temperature rises faster, thus melting and forming a connection. It is capable of welding parts that are transparent on both the top and bottom.

4. Contour scanning laser welding. The laser head or part is servo-driven, causing the laser beam to move across the welding path. There is enough energy to melt and join the parts. This method is suitable for plane to plane welding or for products with a collapse distance of less than 0.1mm.

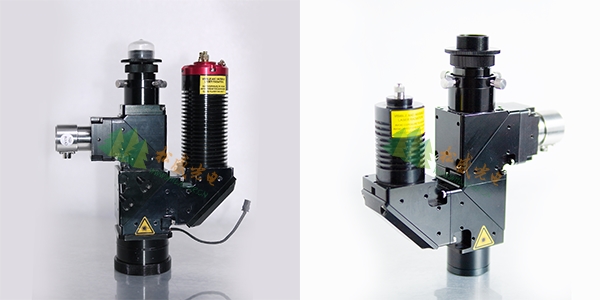

Songsheng Optoelectronics has developed a 976nm coaxial temperature measurement laser welding head and a 2um coaxial temperature measurement imaging laser welding head for two different wavelengths of plastic welding systems. The coaxial infrared temperature measurement and real-time feedback control allows real-time adjustments of the output energy to maintain the consistency of the weld to maximise weld yields. Using the system coaxial CCD camera and monitoring device, positioning and tracking of the workpiece to be welded, to avoid real-time welding process of welding point offset.

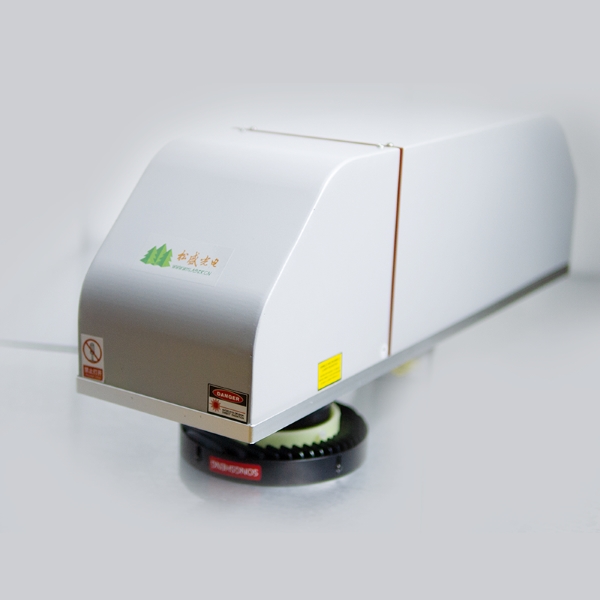

Of course, if the automation manufacturer has the requirement of welding rate, it can be realised by scanner welding. Songsheng Optoelectronics has independently researched and developed an integrated thermostatic scanner coaxial visual scanning welding system for the demand of high speed precision welding, which is not only suitable for precision soldering but also can be used as a precision welding of plastic products. This system is specially designed to meet the high precision positioning requirements of the scanning scanner. The image observed by the CCD is completely coaxial with the focal point of the laser beam, which can be matched with the F-θ lens and the black light source to realise "what you see is what you get" laser processing. The calibrated laser processing absolute position accuracy can reach 0.02mm or less, and can almost overcome the processing position error caused by the temperature drift of the galvanometer when used together with the software.

The current lithium battery industry, from the soft pack to the long thinning battery and even to the battery box internal heat dissipation system, are involved in plastic welding, plastic and metal linking technology, only to continue to optimise and improve the production process, improve the quality and performance of the battery box, for the development of new energy vehicles to contribute.

Contact: Mr.Xiao

Phone: +86-13385280662

E-mail: market001@whlaser.cn

Add: Room 02, Floor 5, Building 9, Gezhouba Sun City, No. 40, Gaoxin 4th Road, Donghu New Technology Development Zone, Wuhan