An automotive micromotor is a small, high power density motor that is widely used in several systems in automobiles. It is mainly used as an actuator for basic and comfort functions in automobiles. Specifically, the automotive micromotor plays a key role in the basic functions of automotive braking, steering, speed regulation and engine cooling, and is also used for the actuation of comfort functions such as automotive air conditioning, warm air, seats, and window rolling.

In addition, automotive micro-motors are also used in control systems to achieve the detection, interpretation, amplification, execution or conversion of electromechanical signals or energy and other functions. Modern car pursuit of passenger comfort and automatic manoeuvrability, micro-motor has become an indispensable component, some cars installed more than 20 micro-motor, movable equipment, whether to do circular motion or other complex movements need to be supported by micro-motor.

Automotive micromotor systems usually consist of components such as micromotors, gearboxes, microactuators, microsensors, microcontrollers, etc., which work together to ensure the normal operation of the vehicle's functions.

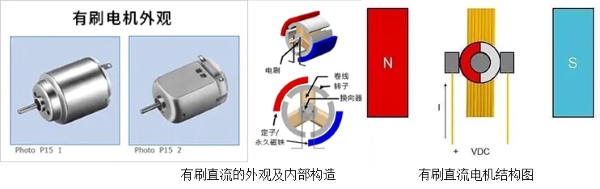

Generally, the motors used to control automotive microelectromechanical systems are classified as DC brushless motors and DC brushed motors, which are used to detect, analyse, manipulate, amplify, actuate or convert electromechanical signals or energy. Various gearboxes can be used to vary the output speed and torque.

Features: high torque, low noise, small size, light weight, easy to use, constant speed operation.

Brushless DC motor:

Brushed DC motors:

Miniature gearboxes:

It refers to the integration of a gearbox and a motor (electric motor). It is also known as miniature geared motor. It is used to reduce the speed and increase the torque to meet the working requirements of mechanical equipment. This combination can also be referred to as a gear reducer or gearmotor. Generally, miniature geared motors are supplied assembled by a gearmotor manufacturer. If the two parts are purchased separately, the combination can be greatly impaired.

Features:

Compact structure, high reliability, long service life, high load carrying capacity;.

High efficiency, planetary gear motor can reach more than 95%, low energy consumption, excellent performance;

Low noise, high precision, precision machining to ensure positioning accuracy

1. as far as the application of micro-motor is concerned:

With the continuous development of automotive technology, people's demand for automotive comfort, environmental protection and intelligence is increasing. There are more and more varieties and specifications of automotive motors, and automotive micromotors are widely used in the engine system, chassis system, body system and accessory system of automobiles. With the development of new energy vehicles, micromotors are also used in automotive thermal management systems and electric vehicle main drive motors.

2. In terms of the context of the development of micromotors:

Micro-motor industry is a technology-intensive industry, originated in Germany, Switzerland and other European countries, and developed in Japan. Since the reform and opening up, China, as a developing country, has undertaken the transfer of automotive micro-motor industry from Germany, Japan and other developed countries, and the spread of technology has gradually shifted to China.

3. Future development trends:

Global automotive manufacturers are demanding technical applications for active safety, intelligence and comfort. Micromotor systems need to continuously develop new structures, adopt new materials, and improve processing techniques to meet the growing application demands. In the future, automotive micromotors will develop towards lightweight, high efficiency, low noise and intelligence. The goals of active safety, intelligence and comfort in automobiles can be realised by micro-motor drives mounted all over the body.

The advantages of Matsunsun's laser soldering process for micro-motor applications:

1. Higher laser processing accuracy, spot diameter of 0.1mm minimum, can achieve the welding of micro-pitch mounting devices;

2. Short time local heating, minimal thermal impact on the substrate and peripheral components, according to the type of component leads to implement different heating specifications to obtain consistent soldering quality.

3. No iron consumption, no need to replace the heater, to achieve high efficiency continuous operation.

4. High precision laser processing, laser spot can reach the micron level, processing time / power programme control, can be in the space of less than 1mm for welding.

5. CCD positioning, what you see is what you get, without the need to repeatedly correct the visual positioning.

6. Non-contact processing, there is no contact welding caused by the stress, no static electricity.

7. Laser for green energy, the cleanest processing, no consumables, simple maintenance, easy to operate.

8. Proprietary technology: laser, imaging, temperature measurement, red multi-light co-axial

Contact: Mr.Xiao

Phone: +86-13385280662

E-mail: market001@whlaser.cn

Add: Room 02, Floor 5, Building 9, Gezhouba Sun City, No. 40, Gaoxin 4th Road, Donghu New Technology Development Zone, Wuhan